With six thermoelectric plants and other gas reuse systems, such as top turbines, it has about 500 MW total generation capacity, which is equivalent to the energy needed to supply 1.4 million homes.

This energy model, improved year by year with new investments and efficiency gains, allows the plant to be self-sufficient in terms of energy. The surplus is distributed to other units of the Group or sold to the public system. Thus, it does not depend on the public system, nor does it use fuel oil. It also provides cost savings and less environmental impact, as it transforms potential air emissions into energy.

Energy Management also includes, through the Energy Efficiency Master Plan launched in 2015, a series of actions to reduce consumption and gain efficiency. The Energy Efficiency Master Plan includes the development and monitoring of energy consumption and generation, always keeping key indicators to maintain the best operational efficiency of the system, thus contributing to the development and maintenance of the unit’s energy management policy.

Climate Change

ArcelorMittal Tubarão’s strategic guidance is to contribute to global efforts to control the causes of climate change and minimize the trend of global warming due to the increase of the greenhouse effect. Since the 1990s, the company has implemented clean technologies to reduce CO2 emissions in accordance with the strategies established in the Kyoto Treaty.

Thanks to that, it was the first integrated steelmaking plant in the world to approve a Clean Development Mechanism (CDM) project. The unit currently has two CDM projects and in 2018, they were responsible for avoiding emissions of 335 thousand tCO2eq.

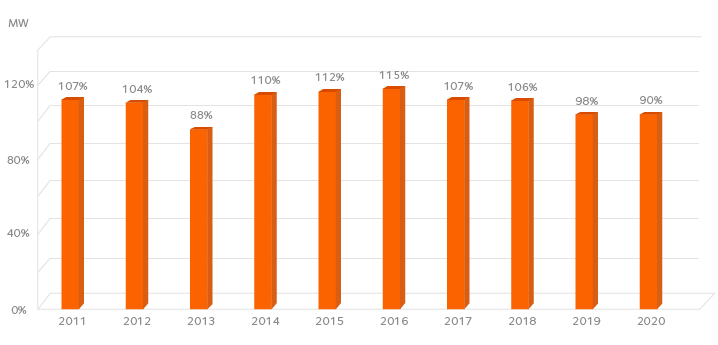

Generation / Consumption (%)