The basis of this management combines:

- Internal controls to avoid waste generation;

- Actions to reduce waste generation as much as possible;

- Efficiency in segregating materials at the plant;

- Investments to develop applications for the reuse or recycling of the waste generated.

ArcelorMittal Tubarão has a specific commercial area to value the materials that are transformed from waste into a portfolio of about 30 by-products. Among them, it is worth highlighting Acerita® and Revsol®, which are already consolidated in the market with both commercial and social value.

The main guideline is to keep the low rate of waste generation per ton of steel produced. The Energy Efficiency Master Plan covers the development and monitoring of energy consumption and generation, always keeping the key indicators to maintain the best operational efficiency of the system, thus contributing to the development and maintenance of the unit's energy management policy.

In order to keep the continuous development of new applications, valorisation of by-products, reduction of internal inventories and compliance with legal requirements, ArcelorMittal Tubarão has multidisciplinary working groups to work on research and contribute to the creation of new technologies.

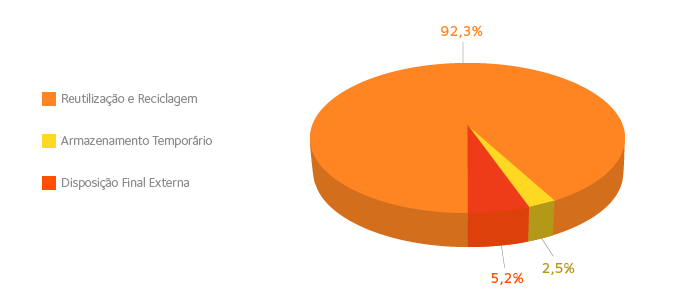

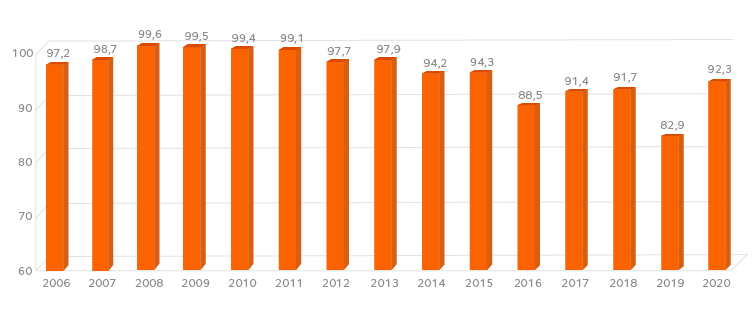

Recycling, Reuse and Commercialization of By-products (%)

Balance of Waste and By-products - Accumulated from 2016 to Jun/20